Birdsell Manufacturing Company

By Roger Birdsell

The author of this history is distantly related to John Comly Birdsell and his family. The common ancestor is James B. Birdsell, who lived in New York State in the mid-18th century and was the great-grandfather of J.C. Birdsell, the inventor of the clover huller and the subject of this history.

Inventing the Clover Huller

In the summer of 1855, John Comly Birdsell, a 39-year-old New York state farmer, assemble a machine that joined the operations of threshing clover, extracting the seed from the hulls, and cleaning the seed in preparation for next year’s crop. The machine was not perfect-it cut the seeds to some extent and had other defects-but Birdsell had faith in his invention. He completed a model of the machine by year’s end and made oath for a patent application on January 19, 1856. One or two improved machines were manufactured in 1856, and the following year a Birdsell thresher/huller was exhibited at the New York State Fair in Buffalo, New York and took first prize.

Before his invention, Birdsell later explained, “clover heads were detached from the stems, preparatory to hulling, by the trampling of horses, by threshing with flails, by cutting with cradles (the two first fingers being covered with canvas and the heads cut off near the place of their attachment to the stems), by removing the heads in the field by an instrument known as a stripper, and after mowing, by ordinary threshing machines.” The heads were also sometimes detached by a machine designed specifically for that purpose. Hulling out the seed was a distinct process. Machines for threshing and those for hulling were often worked at the same time, side by side. Mr. Birdsell went on to explain:

These old processes required the clover to be several times handled; they subsequently took much time and labor, and to that extent added to the cost of clover seed in the market. I conceived that it would facilitate the work and cheapen the product if an implement could be made to thresh the heads from the stems, separate the stems, and pass the heads through a huller, and afterward through sieves under the influence of a fan, all in one operation and in one machine.

Clover was an increasingly popular crop in the early 1800s because it enriched the soil while producing hay for feeding horses and cattle; a characteristic that led to its designation as “green manure.” The bacteria Rhizobium meliloti interacts with the clover plant to fix free nitrogen from the atmosphere in the nodules of the plant roots. Nitrogen enriches the soil, and, after the hay is harvested, the clover roots are plowed under to prepare the field for later crops of wheat, corn or other grains. There was an increasing demand for seed as the popularity of clover spread from the East to the Midwest. By 1850, American farmers were producing nearly 500,000 bushels of clover seed. With clover seed selling from $28 a bushel in Ohio in 1855, for example, the enterprising farmer could buy the new Birdsell Huller and realize a good return on his investment by selling seed to other farmers in his area and commercial seed dealers as well as providing for his own future crop.

The Birdsell Huller was one of many technological advances in the decades following 1820 that transformed American agriculture from subsistence farming to commercial production for expanding urban markets as well as for export. John Deere, James Oliver, and others were improving the plow with cast iron construction, steel cutting edges and scouring moldboards. Harrows, cultivators, grain drills for planting, and mechanical grain reapers and threshers were in common use by 1860. Combines, row crop cultivators, twine binders and many other improvements followed. Steam engines powered the new farm machinery, displacing horse and mule driven treadmills.

The son, Nathan, moved to New Haven, Connecticut and later to East Hempstead, Long Island. Nathan’s great-grandson, James, born in 1728, operated a mill at Quaker Hill and changed the spelling of his surname to Birdsell. His son James was the father of Benjamin. Benjamin moved his family in 1822 to Monroe County in western New York state. The Erie Canal linking the Great Lakes at Buffalo with the Hudson River and the Port of New York City was under construction nearby; it would open in 1825, facilitating the transportation of farm products from the Old Northwest to eastern domestic and foreign export markets. The Upper Mississippi Valley was replacing New York and Pennsylvania as the center of wheat, hog, and corn production. The end of the major Indian wars by 1820; the forced exodus west of the tribes west of the Mississippi in the 1830s; and a series of federal laws that eased the purchase of public lands facilitated the westward march of American agriculture. New technologies were revolutionizing transportation as well as agriculture. Steamboats replaced keel boats and rafts on the rivers; steam engines on rails began moving freight and passengers in the 1840s and 50s. John Comly Birdsell attended district school while helping on the family farm. A bright and industrious youth, he studied for two terms at an academy in West Henrietta, 10 miles south of Rochester, New York, the Monroe County seat, and taught school during the winter months. He was considered a big man physically in his maturity, standing 5-feet, 9-inches and weighing 225 pounds.

In 1836, John Comly rented his own farm near Mendon east of West Henrietta. Three years later he purchased a 284-acre farm in nearby Rush Township. It was a major investment for the period, the average farm size being under 100-acres. An enterprising agriculturist, John Comly began threshing grain and clover for other farmers in the area. John C. married Harriet Lunt on June 7, 1838. Three sons were born in the next few years: Varnum Ogilvie, on January 5, 1841; Joseph Benjamin, usually called Ben, on December 2, 1843; and Byron A., on March 7, 1847. As they matured, the sons helped their father in both farming and making the new clover hullers. A daughter, Harriet Elizabeth, was born in 1856 and died in 1863. A fourth and last son named John Comly (Jr.) for his father, whom the family called Jed, was born June 25, 1859. Despite continued faith in his invention, the senior John Comly Birdsell struggled against great odds. He employed agents to file his huller patent application, but they were negligent and did not act until February 1858; the patent finally being issued on May 18. In the meantime, Birdsell had built a factory and installed machinery on the farm “with money I raised wherever I could.” By the end of 1858, he had sold 26 hullers, but at a loss, not a profit. The average sale price was $220 a machine, bringing in $5,720, but the cost per machine to manufacture was $292.

A Birdsell huller cost a farmer more than purchasing separate threshing and hulling machines. Salesmen for these machines argued that the Birdsell huller would not work. Moreover, competing thresher hullers, which Birdsell believed infringed his patent, were being made and sold. Convinced that “the public had to be gradually schooled into the merits of my invention,” Birdsell often exhibited his machines at state and county fairs “at great expense of time and labor, and a great outlay of money.” In 1859, with debts of over $15,000, Birdsell engaged a partner, Isaac H. Brokaw, who put $500 into the business. Another 230 machines were sold for $55,130 during the next four years-reaching a peak of 102 sold in 1862-but Brokaw, who had quickly withdrawn his original investment, quit the business in the spring of 1863 after taking whatever net profits had been realized during the partnership. Net losses attributable to his patent remained, by Birdsell’s estimate, at $15,000. By this time his farm with improvements had been merged with the huller business. Birdsell valued the entire property at $38,000. The family was living on income from farm operations and huller manufacturing wages paid to family members.

The Move West

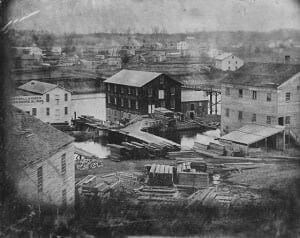

South Bend offered Birdsell several advantages. Lumber was the second largest industry in product value in the county (St. Joseph), and a plentiful supply of hard and soft woods used in making the hullers was on hand. Clover seed was an important local crop; 1,844 bushels were produced in St. Joseph County in 1859. A factory building was immediately available on the west race of the dam across the St. Joseph River in South Bend, providing water power for the machinery Mr. Birdsell would install. The factory was owned by Thomas S. Stanfield, a prominent lawyer and civic leader who had served as Circuit Court judge and Indiana state representative. Stanfield had been a leader in bringing the Michigan Southern and Northern Indiana Railroad to South Bend in 1851, establishing a direct connection to Toledo and the East and to Chicago 90 miles to the west. Birdsell shipped some machinery to the new factory in the fall of 1863.

More machinery and the family arrived in South Bend the following April. They traveled by wagon from West Henrietta to Buffalo, where they took a lake steamer to Detroit. The Michigan Central Railroad-with the machinery on flatcars-carried them from Detroit to Niles, Michigan, and wagons were used to travel the last 9 miles to South Bend. John Comly Birdsell engaged Harrison Ketchum to close the business in New York, with Ketchum to receive a daily compensation plus a fourth of any net profits realized. However, in late April 1864, a fire set by “an incendiary” partly destroyed the office and most of the business records Birdsell had left in West Henrietta. The following August another fire, also set by “an incendiary,” destroyed a storehouse, 23 completed hullers, over 50 frames for more machines and many tools, machinery, and stock. The total uninsured loss from these fires was estimated at $5,790. Birdsell lost more books and records when fire destroyed the St. Joseph Hotel where the family was living in April 1865, and another fire which spread from an adjacent building to his South Bend office in September 1867.

When the family first moved to South Bend, Birdsell rented a two-story frame house at the southeast corner of Wayne and St. Joseph Streets from Aaron Webster, a town trustee and former county coroner. The house was about three blocks from the new factory building. Birdsell purchased the Webster house as the new family home after the St. Joseph Hotel fire.

The Birdsell family arrived during a period when manufacturing was becoming an important factor in the economic growth of South Bend. White settlers arrived in the 1830s, and St. Joseph County had grown to a population of 18,455 by 1860. South Bend, the county seat, had a population of 3,862 and neighboring Mishawaka, 1,488. The economy was predominantly agricultural, with wheat and corn the major crops. The center of early manufacturing was shifting from Mishawaka to South Bend. The South Bend Manufacturing Company completed the dam across the St. Joseph River at South Bend in 1844 with east and west mill races for the generation of power. James Oliver and his associates organized the South Bend Iron Works on the west race in 1855 for the manufacture of iron castings, plows and other products. The Singer Sewing Machine Company would set up a large cabinet making plant on the east race in 1868. The Studebaker brothers arrived in 1852 and began their expanding manufacture of freight and farm wagons and carriages in buildings on the west side of Michigan Street between Jefferson and Wayne Streets.

The 97 manufacturing companies reported in the St. Joseph County by the 1860 federal census grew to 270 by 1870. The $4.4 million in annual value of manufacturing products of 1870 ranked the county fourth largest in Indiana behind Marion (Indianapolis), Allen (Fort Wayne), and Vanderburg (Evansville). Manufacturing employment was reported at 2,463, paying workers annual wages of $958,873. Wagons and carriages were the principal manufactured product, with 15 establishments employing 515 hands and producing an annual value of $929,625. The Singer plant employed 200 and reported an annual value of $500,000. Agricultural implements, furniture, flour and lumber were other major products.

Battling Huller Copyright Infringements

Birdsell’s business continued to struggle after the move to South Bend. The New York farm was sold in 1865 for about $30,000, but the indebtedness remained. Varnum, who was working in the huller factory as a mechanic, and Bend, the company bookkeeper, became partners in the business with their father in 1867. They were to receive half of the profits. Byron was working as a machinist. In 1870, “with a view to escape the burden of debt resting upon the individual members of the firm,” the Birdsell Manufacturing Company was incorporated with a capitalization of $50,000. John Comly as president held $31,000 in stock shares, his three older sons, $18,500, and the plant foreman, Charles McNeal, $500. Varnum was secretary of the new corporation and Ben, treasurer. From 1863 through 1870, 820 hullers were sold. John Comly had begun to file lawsuits against infringers of his patent, starting with the St. Joseph Iron Works Company in Mishawaka in 1862 or 1863. He collected $240 for damages from 16 infringing machines but spent $250 in legal fees and court costs. Ben Birdsell married Ella Van Tuyl, daughter of Dr. David B. Van Tuyl, who helped organize the St. Joseph County Medical Society in 1855, on November 27, 1866. He and his bride established their home at the corner of Wayne and Carroll Streets, a block away from the Birdsell family home. Another pioneer South Bend physician, Dr. Alanson B. Merritt, his wife and three daughters, resided on the same corner.

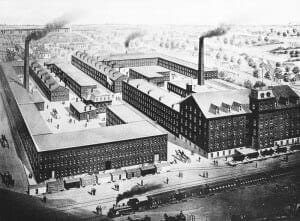

Despite continuing patent infringement problems, the Birdsell business was improving; 296 hullers were sold in 1870 at an average price of $370, a return of $109,520. John Comly made a bold decision: “Having had a fair trade and regained a certain degree of business credit, and, presuming, in view of the successful issue of my various [legal] suits that others would be deterred from infringing, and concluding, also, that our own business would correspondingly increase, we erected extensive works in 1871, at South Bend, at very great expense, and assumed the indebtedness created thereby.” The new works on the southwest corner

The patent battle consumed the time and energies of John Comly and Bend. They hired George V. Glover, a farmer and successful clover thresher prior to the Civil War who was county sheriff from 1868 to 1872, as cashier to handle day-to-day operations of the business during the years 1873-75. John Comly won a great victory in April 1874 when U.S. Supreme Court Justice Noah H. Swayne, sitting in the Northern Ohio District Court, upheld the Birdsell patent, enjoined the defendants from further infringements and awarded costs to Birdsell. Swayne ruled that, despite the delay in securing the original patent in 1858, there was no abandonment of the invention by Birdsell. He held that the 1862 reissue of the patent, while differing in several technical details from the original application, was valid and within the statutory authority of the Commissioner of Patents. He rejected the argument that the Birdsell huller was simply a linking together of existing mechanical devices, not an improvement on pre-existing machines and therefore not an invention qualifying for patent protection. Swayne considered defense claims that the Birdsell huller was anticipated by two other clover thresher-huller machines produced prior to 1855, thereby voiding the Birdsell patent for want of novelty. Citing the evidence produced, Swayne ruled that both machines failed to work and had no practical value. They were not true inventions.

With the federal judgment in hand, Birdsell proceeded vigorously against his patent trespassers, estimating they had produced 4,277 machines by 1878 as compared to 3,060 Birdsell hullers. But, he had limited success in collecting damages. The McDonald and Ashland companies, for example, were insolvent. “There remained nothing now to be done,” Birdsell explained, “but to attack the users of said machines, and, by obliging them to stop their use, to compel them to come to our works for machines they could lawfully use.” Hundreds of suits were brought in several states. Some users settled at $100 a machine to avoid suit, but Birdsell said that collections by settlement or successful suit were offset by the cost of locating the infringing users, enforcing collections and paying agents and attorneys employed in the effort. The users of infringing machines faced with Birdsell demands for compensation considered themselves innocent consumers.

The Michigan State Board of Agriculture, where 8 suits were filed, reported that by 1879 every farmer who had either owned or used an infringing machine had paid a royalty to Birdsell. These farmers considered a number of counter actions; seeking a compromise with the inventor, appealing court decisions to the Supreme Court, petitioning Congress to pass a law ending the collection of royalties from the “innocent” purchaser or user. But no collective action was taken because of the cost involved.

The Birdsell business began to recover in 1876 with a sharp reduction in the manufacture and sale of infringing machines. Sale of 433 hullers at an average price of $370 brought in $160,210, but no dividends were paid “because of the amount owed by us on accounts and bills receivable.” John Comly expected to make a fair profit in the 1877 season by selling 590 hullers, “although owing to hard times and the bad condition of the market, we are obliged to sell our machines for about an average of one-sixth cash and the balance in one and two years.”

Capitalization of the company had been increased to $140,000, with John Comly holding $88,200 in shares, his 3 sons $50,400 and the foreman, McNeal, $1,400. The 3 shareholder sons were now Ben, Byron and the youngest, Jed. The oldest son, Varnum, died at 32 years of age in the family home on December 4, 1875 of internal ulcerations, having been confined to bed for 5 months. The St. Joseph County Register described Varnum as “retiring in disposition” and having “few intimate acquaintances.” He left a small estate consisting primarily of 330 shares of Birdsell Manufacturing stock with a book value of $16,500 which, however, was subject to a $8,095 debt owed to the company. Cash on hand and household goods were valued at $631. The Probate Court approved sale of the stock to the company for $7,137 in 1878 with a cash payment of $2,179, the balance to be paid by the end of 1879. Final settlement of the estate in 1878 left a balance of $4,221 after payment of debts and fees. Emma received half the remaining estate in her own right and the other half as guardian of Hattie and Evelyn.

Jed apparently received the shares purchased by the company from Varnum’s estate. At the end of 1878, with his patent due to expire the next May 18, John Comly filed a petition before Congress to have his patent extended for another 7 years. He said the successor of the Ashland company in Ohio and the Hagerstown, Maryland, Agriculture Implement Manufacturing Company had resumed the manufacture of infringing machines and threatened to reopen the federal case in Ohio. John Comly estimated total corporate and personal receipts to date on account of his patent at $1,181,576. Total expenses were stated at $1,238,437. He estimated personal expenditures in excess of personal receipts from the patent at $73,809. “Having finally succeeded to a great degree in stopping infringers,” he pleaded, “I feel confident that I can, if my patent is extended, reap a sufficient reward from my invention to compensate me for my time, ingenuity, and cost bestowed upon it and for its introduction into public use.”

Birdsell’s petition was first considered by the Senate Committee on Patents. The committee found that the invention was of great public utility, reducing the cost of clover seed from one to two dollars a bushel and thereby increasing the use of clover as a fertilizer. The committee agreed that Birdsell had failed to receive any considerable reward for his invention. Extension of the patent would “not operate as a tax upon the public.” Indeed, “it will be afforded to the public more perfectly and as cheaply by the petitioner if, in the necessary expenditure for its construction, he can be secure of the exclusive right to the manufacture.” The committee in March 1878 recommended that the Commissioner of Patents be authorized to extend the patent if, after a hearing, he agreed with the committee’s findings. However, the bill languished in the Senate while being considered by the House Committee on Patents. That committee report a year later sharply disagreed with the Senate report and, by implication, with the findings of Justice Swayne in Ohio and even the original patent award and extension by the Commissioner. “The machine or combination patented by (Birdsell), being simply the combination of two pre-existing and complete machines into one framework, was not of unusual merit or originality as an invention, and was not intricate in design or abstruse in principle, nor has the patent resulted in such striking or exceptional public benefit as entitles it to the special protection of legislation over equally meritorious patents which annually expire without the very unusual extensions to make a term of 28 years, as sought by the passage of this bill.” The committee said the bill ought not to pass and recommended it be tabled. No further action was taken by either house of the 45th Congress.

In the face of Congressional failure to extend his father’s patent, Ben Birdsell promptly filed applications for patents on improvements to the Birdsell Huller. The first application, filed December 12, 1879, resulted in a patent grant on March 21, 1882. A second application covering 3 more improvements filed April 15, 1881 resulted in another grant on May 22, 1883. Ben also secured a patent on June 19, 1883 for a new system of bracing the gate of a farm wagon with pieces of angular iron.

Years of Prosperity

With Ben assuming primary leadership of the family business, John Comly remarried in June 1879, taking as his wife Mrs. Susan Snelling of Boston. The following year, the newlyweds spent 15 months on a grand tour of Europe, Egypt and the Holy Land. While continuing to hold the office of president of Birdsell Manufacturing, John Comly turned his attention to the affairs of the First Methodist Church, the Masonic Order and the community. He helped organize and served as president of the St. Joseph County Savings Bank. A strong supporter of the temperance movement, he was elected in 1885 to the South Bend Water Works Board of Trustees on the Prohibition Party ticket, with endorsement by the Democratic Party despite his traditional Republican Party affiliation.

Ben had remarried on October 4, 1876. His bride was Olive Tarbell, 20, daughter of Mr. and Mrs. William Tarbell. The Tarbells came to St. Joseph County from Ohio and resided on Wayne Street west of St. Joseph Street near the homes of John Comly and Ben and the new Birdsell factory. Ben and Olive had two daughters, Maude, born in 1881, and Geraldine, born on February 15, 1891.

Jed, John Comly’s youngest son, married Katherine E. Baker on November 22, 1882. Kate Baker was the daughter of Mr. and Mrs. George W. Baker. Baker was secretary of the South Bend Chilled Plow Company. A daughter Bessie Earle (Betty) was born to Kate and Jed on November 2, 1883. Two years later, on November 9, a son was born. The infant died the following day and the mother, four days later.

An “elegant repository” for the sale of the new line of carriages was opened on Wabash Avenue in Chicago. Father and sons celebrated the new plant, and the prosperity which had eluded them for many years, with an elaborate reception the evening of March 12, 1890. A thousand local guests and many from out-of-town joined them in “a shop-warming.” Guests were greeted by arc lights suspended across Columbia Street and uniformed servants escorting them from the carriages to a “great reception hall” on the second floor of the newest building. There were massed floral displays and a centerpiece featuring the letter “B.” There was dancing to a 13-piece orchestra led by the city’s most prominent musician, Lorenz Elbel, and two “callers.” Supper was served in a separate dining room, with guests seated in relays of 200. Ben and Olive, Byron and Evelyn, Jed and his niece Florence, and Horace and his cousin, Libbie, received the guests, who represented the industrial and social élite of the community. The climax was the “surprise” appearance of John Comly, who arrived that evening on the Lake Shore train from the east.

“Thought to be in New York and crippled with rheumatism,” John Comly was alone; his wife Susan was reported to have been too sick to attend. John Comly had little more than four years to live after the shop warming. He died at age 79 on July 13, 1894 while he and Susan were visiting friends, Lyman C. and Flora Egbert, in New Carlisle 15 miles west of South Bend. He had suffered a paralyzing stroke, and his 3 sons and Varnum’s wife, Emma, and daughter, Florence, were with Susan at his bedside when death came in the early morning.

The body was brought to 315 North Main Street, a new home to which the elder Birdsell had recently moved. After services at the First Methodist Church, John Comly was buried in South Bend’s City Cemetery.

John Comly’s estate filed for probate in November and listed assets of $69,843 (just over $1 million in 1982 dollars), primarily his 550 shares of company stock with a book value of $55,000. The court approved Ben’s purchase of his father’s personal property from $963. John Comly’s will left $3,000 to Susan plus an annual payment to her of $3,000. Susan also received several hundred dollars on promissory notes executed by her husband. Each of the 7 surviving grandchildren were to receive $1,000 from the estate; payable immediately or upon their 21st birthday. Birdsell Manufacturing stock was to be divided evenly between the 3 sons. After two years, the trustee of the estate reported sale of a 98-acre farm for $5,880 and the old family home property for $8,000. Birdsell Manufacturing stock held by the estate over this period earned dividends of $8,000. Total value of the estate at this time was placed at $78,843. The trustee retained 150 shares of stock and $3,319 in cash to pay the remaining legacies and Susan’s annuity. Ben, Byron, and Jed divided the remaining 400 stock shares. Susan died in December 1909, and the estate was finally closed in 1912 with the $1,000 payment to the youngest surviving grandchild, Geraldine.

The prosperity of the company inherited by the 3 Birdsell sons in 1894 is indicated by the dividends paid to John Comly’s estate over two years, an annual return of about $27 a share. John Comly was receiving about $4,000 a year in dividends and each son about $1,300, as well as the salaries they earned. With the extra inherited stock, each son could look forward to an annual dividend income of about $5,000.

Ben became president of Birdsell Manufacturing, retaining the office of treasurer. Byron was vice president and Jed, secretary. Ben’s son Horace, usually called Chub, who had received a business administration degree from the University of Michigan, became cashier. Birdsell Manufacturing had survived and prospered despite difficult times for American farmers.

Agricultural product prices had declined irregularly but persistently since the end of the Civil War. But, in 1897 an agricultural boom started that continued until 1920. The index of prices for all farm products, which had fallen from 119 to 1869 to 53 in 1896, rose to 100 in 1910. The Birdsell company and family contributed to South Bend’s continued industrial growth. By 1890, St. Joseph County with 42,457 inhabitants was the largest in the region, surpassing LaPorte County to the west, Elkhart County to the east and Berrien County in Michigan to the north. One out of two county residents, 21,819, lived in South Bend, and nearly 60% lived in South Bend or Mishawaka with its 3,371 inhabitants. The population was still overwhelmingly white with only 340 Blacks reported in the 1890 census. Twenty percent of the population was foreign-born, the majority of them, 6,160, living in South Bend. Polish immigrants were arriving in increasing numbers, 2,294 reported in the county in 1890.

By 1890, the $13,547,813 invested in the manufacturing plant and equipment in St. Joseph County nearly matched the $14,165,600 investment in agriculture. Farms were becoming larger, 42% having more than 100 acres. However, the annual value of manufactured products greatly exceeded the annual value of farm products. St. Joseph County now ranked fifth in value of manufactured products in Indiana. South Bend factories produced 80% of the manufactured product value in St. Joseph County, employing a workforce of 6,088 with annual wages of $2,842,104. Wagons and carriages accounted for nearly $4 million in annual product value and agricultural implements, more than $2.4 million.

The enlarged Birdsell factory could produce 1,500 hullers and 15,000 wagons annually. Employment apparently varied from 400 to 700 during this period. While no production or sales statistics after 1877 have been located, wagons and hullers were the mainstay of the business. Carriages, surreys, phaetons and buggies were produced, but they are mentioned in only one surviving Birdsell advertisement; most of the space being devoted to promotion of huller and wagon sales. A Birdsell wagon catalog of the 1890s priced the one horse wagon at $61 and the smaller farm wagons at $54 to $69.50 depending on the particular model and extras bought by the purchaser. Prices for the narrow-tired standard wagon ranged from $75 to $126 and for the mountain wagon, from $88 to $141.

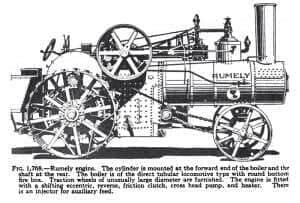

A 1927 flier listed prices of $295 and $395 for two different huller models. The huller was a large piece of equipment weighing from 4,800 to more than 7,000 pounds depending on the model. Mounted on a large wooden wagon or “truck,” the hulling machinery moved the seed heads separated from the stalks through a series of shakers and sieves that removed the hulls from the heads and cleaned the seed. A winnowing fan blew the lighter huff chaff from the heavier seed. A broad belt from an 8-horsepower standing engine powered the machinery connected by a series of belts, chains and gears. Three operators attended the huller; one a feeder forking cut clover hauled in wagons from nearby fields into the huller. A windstacker blew the stalks and chaff onto a nearby stack. Birdsell claimed the huller was so efficient that no valuable seed was blown onto the stack with the chaff.

Birdsell also manufactured a machine fixed to the factory floor that hulled and cleaned clover head threshed from the plant at another location. Birdsell sales and promotional literature for both hullers and wagons stressed quality, durability and reputation. A typical 35-page booklet on the huller called it “nearly as perfect as it is possible for human skill and intelligence to make it.” Birdsell believed “in doing business along safe and conservative lines,” relying on “satisfied customers” rather than “thousands of dollars spent on advertising.” Promotional material contained pages of letters from customers praising the durability, performance and longevity of the huller. A huller made in 1887 was said to be still working with no major repairs in 1914 (see the booklet below).

The name Birdsell defined the product: “There is Nothing Better Made” proclaimed a surviving advertisement. Another brochure promoted “The Wagon of Quality” as the best and cheapest for the owner because: “When you buy a Birdsell you are practicing Economy.” This brochure cited weather resistant air dried and sealed woods, strong concave wheel shoulder spokes, iron against iron friction points, and features that kept dust out of the grease in the wheel box, made pulling easier for the horses and allowed sharp turns in close quarters.

The Birdsell steel “skein” wagon featured a tapered steel sleeve shrunk onto the collar ends of axles made of hickory, resulting in a stronger axle than one reinforced with cast iron. Birdsell wagons and hullers consumed large quantities and varieties of wood, including birch for wheel hubs, white oak for felloes, yellow poplar for the wagon box and Norway pine for the box bottom. Agents selected the best lumber, which was air dried for 3 to 5 years in sheds near the factory; a process slower than kiln drying but insuring durability. Paint was applied by brushing rather than dipping, and a final coat of varnish was applied to the wagon or huller. As production increased in volume, much of the foundry work was sub-contracted. Completed hullers were usually stored in sheds pending spring shipment to dealers and agents.

The company maintained branch offices in a number of cities in the Midwest and in Toronto, Canada. By the outbreak of World War I in 1914, Birdsell claimed to manufacture 95% of the hullers made in the United States, with a fourth of the production going to an increasing export market. The company vigorously promoted the virtues of both clover and the Birdsell huller through booklets like “The Clovers: How to Sow, Grow, Harvest and Save the Seed,” published in 1896. It warned against “so-called hulling attachments to grain threshers” which failed to clean the seed properly. Despite the title, the booklet also described in detail the growing and harvesting of alfalfa, another nitrogen producing forage crop spreading in popularity from the South and West to the Midwest and east with the development of a winter-hardy hybrid of the plant.

A separate line of machines for threshing, hulling and cleaning alfalfa had been developed by Birdsell. “The Clover Leaf,” a four-page newspaper published by Birdsell in June 1876, printed the entire printed opinion of Judge Swayne upholding the Birdsell huller patents. It claimed a circulation of 50,000 and a readership of 500,000. “The Business of Birdsell, Putting Character Into a Machine” was published in 1920 with an embossed cover and contained 68 pages of text illustrated with numerous photographs of the huller and its components. A poem by James Whitcomb Riley, “The Clover,” was featured in this publication.

Olive was a founder of the Progress Club, the pre-eminent women’s literary association, in 1899 and was active in the South Bend YWCA. Ben succeeded his father as a director of the Savings Bank. He was a member of the Country Club and the Commercial Athletic Club; became a director of the Associated Charities; served as president of the Municipal League organized to improve local government; took a leading role in erecting the Civil War Memorial outside the County Courthouse in 1899.

His bachelor son Chub helped found the Indiana Club, organized by the city’s younger businessmen, and was active in the social life of that set. An amateur photographer, Chub recorded on film the fine horses and glittering carriages and other scenes of that time period.

Jed Birdsell, who had remarried on October 4, 1899, built his mansion in 1902 at 1249 E. Jefferson Blvd. The new Mrs. Birdsell was Jane DeFrees, daughter of Archibald DeFrees, a carpenter and contractor by trade who was active in local Democratic politics. Their new home with mahogany paneling and an elaborate curved main staircase, also designed in a Romanesque and modified Queen Anne style by Parker & Austin, was dominated by a field stone turret flanking the front porch.

Jed had purchased the land for his new home from the heirs of John Studebaker–it had been farmed by the Studebaker family–for $5,000 and engaged to build a “good and substantial dwelling house” with a setback of at least 100 feet at a cost of, at least, $15,000 in the purchase agreement. Before moving into the new home, Jane gave birth to a son, John Comly Birdsell III, on July 15, 1900. A second son, Archibald, died 10 months after his birth in 1906, and a third son, Joseph Benjamin, was born on March 20, 1908.

Byron Birdsell–who was to be described like his brother Varnum as a man of “retiring disposition”–and his wife Evelyn moved into a substantial but more modest home at 714 W. Washington Street about 1884 after living for a brief period on a farm he purchased in Harris Township (Mishawaka, Indiana).

The third Birdsell generation in South Bend, John Comly’s grandchildren, were beginning to establish their own families in the 1890s. Hattie, Varnum and Emma’s older daughter, married Dr. Thomas A. Drake and settled with her husband in Prairieton, 9 miles south of Terre Haute, Indiana. The younger daughter, Florence, briefly married to a Herbert H. Silliman, wed Horace Leeper Greene on June 15, 1899. Greene was the son of Daniel Greene, a St. Joseph County pioneer/settler for whom Greene Township was named. His mother was Mary Leeper, daughter of Samuel and Elizabeth Leeper, who settled in South Bend in 1849 and gave their name to the city’s Leeper Park.

Daniel Greene invested in the South Bend Chilled Plow Company when it was organized by Kate Baker Birdsell’s father, George W. Baker, and his partners. Horace Greene became an accountant with the company and later bought an interest in the Anderson Foundry in South Bend. Horace and his first wife, Addie, who died in 1895, had a daughter, Marie, who married William C. Sibley.

When Horace bought out his original partner, Anderson, he incorporated the business as the South Bend Foundry Company and brought son-in-law William into the business. William Sibley was one of the three sons of Irving Augustine Sibley, a native of Buffalo, New York, who moved to South Bend in 1885 and established a hardware business.

Another son, Irving Jr., married Jed and Kate Baker Birdsell’s daughter Betty on October 4, 1904. The couple lived in Danville, Illinois for a few years, but returned to South Bend, and Irving became secretary of South Bend Foundry. A third Sibley brother, Frank, was also connected with the South Bend Foundry.

Byron and Evelyn Merritt Birdsell’s daughter, Libbie, married on

Engman and Matthews sold their interest in Malleable about 1912 and organized the Engman-Matthews Range Company in the old Singer Sewing Machine cabinet plant on the East Race (now Oaklawn Mental Health facility). Engman moved the business to Goshen, Indiana in 1921, at the same time making a gift to the city of South Bend of the new Engman indoor Natatorium, the site of his home in the 1000 block of West Washington Street.

Ben’s health began to fail, and in the spring of 1906 he asked Byron and Jed to manage the business while he undertook a restorative trip to the Orient with Olive and their younger daughter, Geraldine. They reached Los Angeles, but turned back in the early summer as Ben became increasingly ill. He died of kidney failure and heart disease at the age of 62 on September 27, 1906. His estate consisted primarily of 1,030 shares of Birdsell Manufacturing stock with a book value of $50 a share, though he also owned five shares of Merchant’s National Bank stock valued at $400. Probate records show that about 280 of these shares were sold to raise cash to meet demands against the estate. When the estate was closed in November 1909, Olive and Ben’s three children had received $34,400 in dividend payments from stock held by the executor. The estate also paid off promissory notes held by Jed, $3,954, Varnum’s daughters Hattie and Florence, $1,700 each, and two other creditors. Olive received the personal property valued at $2,995. Two-fifths of the remaining estate at the final closing, $1,714 in cash and 750 shares in company stock, went to Olive and a fifth each to Chub, Maude and Geraldine.

With his father’s death, Chub, who had established himself in bachelor quarters at the Rushton Apartments, 501 W. Washington Street, apparently retired from any active role in the company. Byron became president and Jed, secretary-treasurer, of Birdsell Manufacturing.

The last granddaughter to marry was Geraldine, who on April 29, 1913, wed Reed Parker, son of a local attorney, Samuel Parker. Reed was a graduate of Harvard University who became a reporter for the Hearst newspaper chain, moving with his bride to the Detroit area and later to Chicago. Byron died on February 24, 1917 at the age of 69 after a year’s illness of complications of Bright’s Disease. Evelyn, who suffered from diabetes, declined after Byron’s passing, dying in October of the following year after being bedridden for weeks from a fall that broke her hip. Byron left a substantial estate of $243,993 (nearly $2 million dollars in today’s money) divided equally between Evelyn and their daughter Libbie Pace after taxes.

Years of Decline

With the death of Byron, Jed became president, treasurer and general manager of Birdsell Manufacturing, with his son-in-law Harry Engman as vice president and W.J. McIntyre, a long-time employee, as secretary. World War I had damaged the huller business with a decline in exports as well as domestic sales as farmers concentrated on the production of food grains. Company spokesmen were optimistic with the end of the war, however, reasoning that huller exports would rise to pre-war levels and that “the farm wagon is a matter of economic necessity to the farmer,” particularly in the South.

Increasingly, the spokesmen was Perry G. Stahly, the firm’s sales and advertising manager since 1908. Stahly was the son of a farmer and contractor in the Nappanee, Indiana area who came to South Bend after two years of high school to study stenography and bookkeeping at a commercial college. He worked at the Singer plant while a student, and in May 1900, was hired as a stenographer and general office clerk at Birdsell. Six years later, he was promoted to a sales position and began extensive business travels abroad as well as in the United States.

Prosperity returned to neither the Birdsell company nor the American farmer in the 1920s. Farm product prices began to fall in the summer of 1920, wheat dropping from $2 to $1 a bushel, and thousands of farmers went into debt and bankruptcy. These conditions continued throughout the 1930s until World War II provided the stimulus for recovery. Jed relinquished the position of general manager and active direction of company affairs to Stahly in 1927 when declining company fortunes were forcing dramatic changes in the life-styles of family members.

By 1926, Olive had moved out of the mansion she and Ben had built on West Colfax, and by 1928 she apparently was working as a saleslady to help support herself. Jed and his family left their mansion on East Jefferson in 1928. Jed’s older son John, who had attended a preparatory school in the East but failed to graduate, worked as a clerk at Birdsell Manufacturing until about 1930, when he was able to find a job as a regional salesman for the International Harvester farm equipment company. Somehow or other the younger son, Joseph, was able to continue as a student at Massachusetts Institute of Technology.

The Birdsell company sold the wagon business for an undisclosed price to the Kentucky Wagon Company in Louisville the year after the New York stock market crash in the fall of 1929. Kentucky Wagon also bought the Studebaker wagon business about the same time. In December 1931, the South Bend News-Times reported the imminent sale of the huller business to Allis-Chalmers Company of Milwaukee, Wisconsin. The South Bend Tribune reported Stahly’s denial of the report. Stahly admitted there had been negotiations in the past but insisted no sale was currently under consideration or anticipated. However, on January 19, 1932, sale of the huller business to Allis-Chalmers was confirmed. The price was $58,000 and did not include any of the buildings or fixed equipment in South Bend.

Allis-Chalmers at the time was expanding its farm equipment operations, having purchased the Advance-Rumley Company of LaPorte, Indiana, where tractors and grain-harvesting combines were manufactured. Despite the sale to Allis-Chalmers, Stahly insisted the “coming season’s quota of hullers will be made here.” He declined comment on reports the Grand Trunk Railroad had purchased the plant buildings east of Columbia Street for warehouse use, though in fact such a sale had been made.

Jed Birdsell said the Birdsell name would continue, noting that several hundred hullers and 24,000 Birdsell wagons were still in use. However, there is no record of any more hullers being made in South Bend, and none were produced by Allis-Chalmers in LaPorte. Allis-Chalmers did continue to sell previously made hullers acquired in the purchase of the Birdsell business.

On a Sunday evening, April 24, 1932, Chub Birdsell, having pulled the covers over his night-clothed body in his Rushton Apartments bedroom, leaving his arms free, pressed a .32 caliber revolver against his right temple and fired one shot. The body was found the next morning by a maid. Another maid, who had seen him late Sunday morning, reported that Chub discussed the weather and appeared, “customarily cheerful.” Chub left a brief note on his writing desk stating that he had no reason for living or dying. His bankers, however, confirmed that he had been living off savings accumulated when he had a steady income from Birdsell stock dividends. A News-Times reporter recalled the turn-of-the-century days when Chub led the younger set of the city. “In his apartment he kept a store of treasures from the mauve decade, heavily framed hunting pictures, old steins, and the books, clothes, and the furnishings of the previous generation.” Chub had become a town character, spending much of his time in the lobby of the Oliver Hotel, two blocks from his apartment, constantly smoking cigarettes. “He would be the first to catch a misprint or misspelling in a sign, and one of his faithful performances each day was the keep the magazine racks in order.” Occasionally he would take in a motion picture.

In a will completed three days before his suicide, Chub left his Birdsell company stock to Stahly, his personal possessions to his Uncle Jed and what little was left to two cousins on his mother’s side of the family.

Three quarters of a century had passed since John Comly assembled his first huller on his New York state farm until the last machine was made in South Bend in the summer of 1930. The great battle against the infringers had been won. John Comly had the foresight and courage to build one of the largest factories in South Bend and employ a skilled labor force. He survived and prospered as the manufacture of farm implements and machinery was consolidated in fewer but larger establishments. But, despite the success of the huller and wagon lines, John Comly and his sons failed to diversify either their product mix or their personal investments. They continued to rely almost entirely on their salaries and stock dividends from Birdsell Manufacturing.

The tractor powered by the internal combustion engine doomed the horse-drawn farm wagon; gasoline and diesel powered trucks replaced the freight wagons. As early as 1909, 30 companies were producing 2,000 tractors a year. There were about 920,000 tractors in use on American farm by 1930 and 1.6 million by 1940.

A number of factors reduced demand for the Birdsell huller. Commercial fertilizers were replacing rotation crops like clover and alfalfa, liming and animal manures for soil regeneration. The use of nitrogen fertilizers doubled from 1920 to 1920 and increased 50% in the next decade. Farmers were growing less clover with the decline in the horse population. The national acreage devoted to red clover, the principal variety, and timothy declined from a peak of 36 million acres in 1922 to 22 million in 1940. During that same period the acreage devoted to soybeans grew five-fold. Soybeans also added nitrogen to the soil, had a better yield per acre than clover and were a primary feed for the increasing number of dairy cattle. Finally, with the prolonged agricultural depression of the 1920s and 1930s, few farmers were in a position to invest in a new Birdsell clover huller.

John Comly’s last surviving son, Jed, lived at 733 West Washington Street the last few years of his life. He suffered from heart disease and was admitted with pneumonia to Epworth Hospital, where he died on April 3, 1937 at the age of 77 from the effects of prostate cancer. Although a member of the city’s original volunteer fire department, the Rotary Club, the Indiana Club and the Country Club, Jed was described as a man who “lived his life with very little hue and cry.” He left an estate of $184 in cash and 4,560 shares of Birdsell Manufacturing stock with a book value of $9,120. The probate court was advised, however, that the stock had no market value and that the company had been in a state of dissolution since 1932. When the estate was finally closed in 1941, Jed’s wife Jane and his three children received the valueless stock shares and $1,648 in cash. Jane lived until the age of 98, dying on September 15, 1970 in the Carlyle Nursing Home after living for several years in a one-room apartment in the Morningside Hotel across Williams Street from the mansion her in-laws Ben and Olive had built.

Olive Birdsell’s final residence was 812 E. Jefferson, and she died after a lengthy illness of an inflammation of the parotid (salivary) glands on March 28, 1942 in St. Joseph’s Hospital, leaving a modest estate of $12,766 after debt deductions. Trust income went to Olive during her lifetime and then to her two daughters, Maude and Geraldine. The trust was dissolved in 1962 with a final payment of $2,116 to Olive’s four surviving granddaughters.

The Birdsell enterprise had survived destructive fires in New York state and South Bend in the 1860s, but the business was not to rise again from a conflagration fanned by a strong northwest wind that destroyed the factory that John Comly Birdsell built in 1871. The blaze broke out the night of September 15, 1938, and crowds estimated at 25,000, drawn from the nearby annual downtown merchants window display, watched as 10 South Bend fire companies fought to keep the fire from spreading to nearby buildings. The alarm had been turned in by employees of a wholesale butter and egg business occupying the former Birdsell buildings east of Columbia Street. Sprinklers were turned on in the Grand Trunk Warehouse east of Columbia, and neighboring residents sprinkled their roofs. The roof caved in and only the walls of the 1871 plant were standing the next morning. Stahly estimated the fire loss at $100,000, of which $70,000 was covered by insurance, though another officer of the company said insurance only covered $34,000. Stahly said workmen had removed machinery from the empty factory building for a proposed lease of the building as a warehouse to the federal Works Progress Administration. The cause of the fire was said to be either a spark from an acetylene torch used by a worker or a cigarette dropped by either a worker or by a trespassing boy after the workmen had left for the day.

A New Corporation

After the 1938 fire, Stahly told The South Bend Tribune that Birdsell Manufacturing was still in the process of collecting on farm notes issued to purchasers of wagons and hullers. Most of his energies, however, were focused on a new company bearing the Birdsell name.

The Birdsell Corporation articles were approved by the Indiana Secretary of State July 28, 1937. The incorporators were Stahly; George W. Blair, vice president of the Mishawaka Woolen Manufacturing Company, and Elias W. Stickland, formerly with the Studebaker Corporation legal department. The new corporation issued 3,000 shares of preferred stock with a $100 a share par value and 200,000 shares of common stock with no par value. Stahly received 540 preferred shares and Strickland 110 preferred shares “for services.” In organizing the Birdsell Corporation, Stahly offered to exchange one share of the new corporation stock with a par value of $100 for 20 shares of old Birdsell Manufacturing Company stock. Stahly organized the new company to promote a new type of washing machine patented by William Rocke, who became vice president in charge of sales.

Their idea was to perfect the new machine, which dispensed with the agitator part of the conventional washing machine, and licensed its manufacture to other companies. Rocke had devised an ‘impeller’ located in the central housing and driven by an electric motor to generate a water action that ‘flexed’ the clothes in the machine. The “water-flex” system alternately expanded and contracted the clothes, flushing away the dirt. The new system was said to eliminate wear and tear on clothes stirred by the agitator in conventional washing machines. A demonstration machine had been made and was introduced at a press conference in South Bend in August 1937.

The “water-flex” system flopped. In a lengthy 1951 financial report to stockholders, Stahly blamed the failure on suspension of washing machine production during World War II, inability to attract sufficient capital and alleged collusion by the washing machine industry to refuse and/or demand exclusive licensing of the new machine. He claimed the industry feared loss of investment in plant and equipment if the new machine was successful and decided to meet post-war demand by making agitator washing machines. The “water-flex” system was introduced at the same time Vincent Bendix, a South Bend manufacturer of automotive brake systems, began to market the new Bendix washing machine. Stahly claimed Bendix succeeded where he failed because Bendix had sufficient capital and switched from a “cylinder” to an agitator system.

The Board of Directors, with Stahly’s son, Preston, serving as acting secretary, voted to liquidate The Birdsell Corporation in April 1965, by selling remaining tools, dies and parts to pay the bill for their storage. Promotion of the “water-flex” washing machine was barely underway when Stahly became interested in a mechanical razor patented by a Chicago inventor, Russell P. Harshberger. They signed an agreement in March 1940, by which Stahly would manufacture and sell the razor, paying royalties to Harshberger.

The blade of the razor was powered by a spring in the handle rather than the electric motor that was to become the basis of the automatic razor industry. Stahly announced production of the Stahly Live-Blade Razor in November 1945. Production was to be in Chicago because of a lack of trained assembly workers in South Bend required to fill orders for “tens of thousands” of razors. A contemporary ad said a turn of the handle moved the blade “in an even flow of over 3,000 gentle strokes per minute, cleanly slicing off whiskers…with watch-like precision.” Stahly told The South Bend Tribune that administrative and sales offices for the razor would remain in South Bend, where he hoped to move production in about two years.

He had organized another company, Birdsell Laboratories, Inc. to promote the razor, but changed the name to Stahly, Inc. to reflect the name of the product. The razor went the way of the washing machine.

By the 1960s Harshberger, who had moved to California, was complaining that Stahly failed to pay all royalties for razors sold. Stahly denied the charge and made changes in the razor, which, he was advised by counsel, did not infringe Harshberger’s patent. Stahly was issued a trademark for the Live-Blade Razor in 1965 and considered applying for a patent. However, at the same time, he was attempting to sell Stahly, Inc. inventory and assets for $60,975 after all liabilities were paid.

There is no evidence he either received a patent or sold the company. Stahly had maintained a “country estate” in suburban Roseland north of South Bend, but, before his death on March 31, 1972, in the Carlyle Nursing Home, he resided in the Morningside and LaSalle Hotels.

Death and Remembrance

When Jed and Jane Birdsell’s sons, John and Joseph, were boys, they became avid hunters of arrowheads and other relics of the Indian tribes who had once lived in the area around South Bend. Archaeology became a consuming vocation for John.

He married Marie Ann Rogers, remembered by contemporaries as a great beauty, on September 24, 1927. While John was selling farm machinery for International Harvester in the 1930s, Marie worked as a clerk in the regional Standard Oil Company office. John became regional manager for International Harvester by 1945 and retired in 1966. He and Marie lived at the Washington-Colfax Apartments on W. Washington Street.

In the late 1940s John discovered the site of a 1,000 year old Indian village at Moccasin Bluff, north of Buchanan, Michigan. He worked beside archaeologists from the University of Michigan in excavating the site, donating artifacts to the university’s Museum of Anthropology as well as building a personal collection in his apartment. He published a paper, “The Moccasin Bluff Site and the Woodland Cultures of Southwestern Michigan.”

Friends remembered John as a rugged individualist who loved to make the women blush and wasn’t one to suffer fools gladly.

Marie Rogers Birdsell died in their apartment on February 28, 1978 after an extended illness. The couple had no children, and a friend later remembered John being greatly disturbed over Marie’s death.

On Wednesday, December 5, 1979 John drove his new red Datsun automobile to a spot along the St. Joseph River in the 1800 block of Riverside Drive. He had visited the area often, feeding the ducks with corn he kept in his pockets and observing the wildlife. Another car was along the riverbank, a 1971 Pontiac with temporary Illinois license plates, and John talked to the two teenagers, a boy and girl, who had driven up in that car. The Pontiac had been involved in a traffic accident at Michigan and Navarre Streets earlier that morning. John and the boy tried without success to start the Pontiac.

The next morning, John returned to the riverbank, where the teenagers had slept in the car overnight. Sometime that Thursday afternoon, John and the boy had a violent argument. Suddenly, the boy, John Meador, 17, seized a tire iron. John pulled a .38 caliber pistol from his pocket. The girl, Gina Wilkerson, 14, who had been sleeping in the back of the Pontiac, woke. Later she testified that she heard the old man say either ‘don’t kill me’ or ‘I’ll kill you.’ Meador swung the tire iron, knocking the pistol from John’s hand. Meador grabbed the pistol and fired a shot. John fell to his knees, attempted to rise, was kicked in the face by Meador, who fired a second shot.

Meador and Wilkinson threw their belongings into John’s red Datsun and drove off. A passing utility worked called police after being alerted by nearby residents who had witnessed the shooting from a distance. John was taken by ambulance to Memorial Hospital, where he died at 5:05 p.m. At first, police were unable to identify the shooting victim. An extra set of car keys was traced to the dealer who sold John the Datsun, and John’s body was identified by his sister-in-law, Ruth Rogers. Private funeral services were in December followed by burial in a Highland Cemetery mausoleum.

When the first John Comly Birdsell journeyed west from New York in 1863, seeking a new location for his family and his huller business, he brought along his youngest son Jed, then nearing his 4th birthday. They took a lake steamer from Buffalo to Detroit and then a train to Niles, where they rented a buggy and drove the 9 miles to South Bend. Sixty years later, Jed vividly recalled how they stopped at the top of Leeper Hill and gazed south across the St. Joseph River: “A bright spring morning, the winding river, a forest of fine big trees on either side and a clump of buildings known as the town, a sight never to be forgotten.”